6 what qc is required when using a refractometer|refractometer maintenance guide : purchaser The importance of good quality control (often referred to as QC), whether in food, beverage, pharmaceutical or chemical manufacture, is to ensure all finished product is consistent and meets the required (and often regulated) specification. Resultado Mega Sena 2490 11 de junho de 2022 - Sábado C.

{plog:ftitle_list}

Top Entertainment - Super Reputation. 710ms. fc777mm.com

The importance of good quality control (often referred to as QC), whether in food, beverage, pharmaceutical or chemical manufacture, is to ensure all finished product is consistent and meets the required (and often regulated) specification.The RFM-T Series is a range of digital refractometers made in Europe from .Bellingham + Stanley offers one of the largest choices of digital refractometers .The ADP600 Series of Peltier temperature controlled multi-wavelength polarimeters .

Vist our page dedicated to the different types of refractometer calibration .The importance of good Quality Control (QC), whether in food, beverage, pharmaceutical or chemical manufacture, is to ensure finished product is consistent and meets the required .

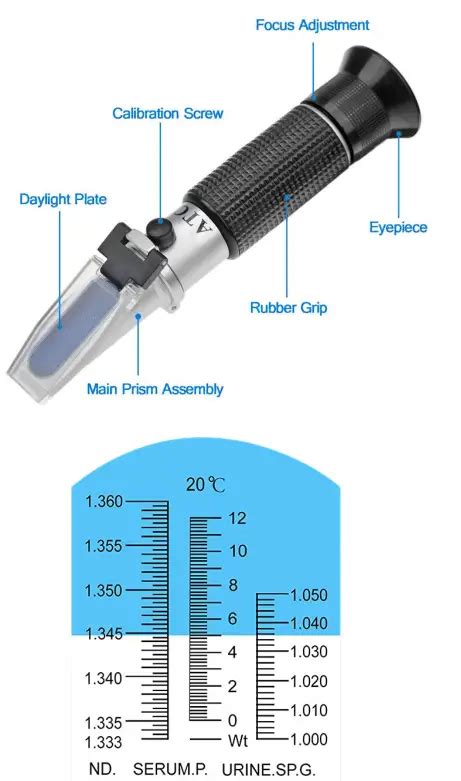

This manual describes the proper operation and care of this state of the art instrument. The AR200 is capable of measuring % Solids (Brix), % Solids-TC (Brix . If there is a discrepancy with the reading and the value you know to be true, then you will need to calibrate your refractometer. The reading error (or tolerance) taken at a set .A refractometer must be sensitive to the required accuracy, with features that eliminate potential confounding issues,” says Chapman. A 0 handheld refractometer should not be used for pharmaceutical QC, but such an .This guideline reflects requirements and provides recommendations for use in planning, recording, and monitoring performance qualification, function checks, calibration

Treat handheld refractometers with care for continuously accurate results. Optical and digital handheld refractometers require little maintenance, often only requiring a zero .to make sure it meets the required, possibly regulated, specification. Good QC has an impact on profits too. Most people define QC as quality control but it can also be interpreted as quantity . In the last blog we discussed the benefits of taking time to choose the right refractometer for you, competencies and sample preparation. Part 3 of our Refractometer .This guideline reflects requirements and provides recommendations for use in planning, recording, and monitoring performance qualification, function checks, calibration . verification, and preventive maintenance activities for general . 6. 2 3.14 Refractometers

A significant difference between refractometers was found, F (1,8) = 6.32, p = 0.04, as well as a significant difference in TDS with the use of a filter, F (1,8) = 10.3, p = 0.01, and a significant interaction between the use of a filter and the .

refractometer results

refractometer requirements

On initial use, remove the controls from the refrigerator and allow to reach room temperature prior to testing. b. Remove cap and invert bottle. Apply urine control to refractometer as you would a patient sample. c. Read the refractometer according to the procedure above. Record result on the Quality Control Log Sheet. 5.0 Instrument Features 6 6.0 Automatic Temperature Compensation 7 6.1 Temperature coefficient and correction calculations 7 7.0 Installation Procedure 7 7.1 Set Up 8 8.0 Sample Reading 10 9.0 Menu Options 11 10.0 Daily Single Point Calibration 12 11.0 Multipoint Calibration 13 11.1 Calibration Oils 14 12.0 Channels 15

To lay down a procedure for Operation & Calibration of refractometer. SCOPE: This procedure is applicable for procedure for Operation & Calibration of refractometer. RESPONSIBILITY: QC Officer/ QC Executive. ACCOUNTABILITY: QC Manager. PROCEDURE: Operating Procedure. Ensure that instrument is clean and free from dust. Switch ON the mains.

What are your Requirements? If your manufacturing or testing procedures call for the measurement of a few parts per million, you may need to invest more than you would with the PR-111 Inline Process Refractometer. . But if, like the vast majority of companies that use refractometers, your equipment readings need to be accurate and repeatable .A refractometer consists of a light source, filtered to a single wavelength, which is directed towards the prism-sample interface by a converging lens. . If you reject all cookies, only technically required cookies will be used. You can also withdraw your consent at a later time by accessing the Cookie Settings. I accept all cookies including . Refractometers are commonly used as a quantity control tool within factories and laboratories. The importance of good quality control (often referred to as QC), whether in food, beverage, pharmaceutical or chemical manufacture, is to ensure all finished product is consistent and meets the required (and often regulated) specification.

Measure the refractive index and concentration of liquids, gels and solids using laboratory refractometers from Anton Paar – the universally applicable and user-friendly Abbemat series. Simply take your pick depending on the accuracy, temperature range and level of automation you require - you can be sure to find a digital refractometer model . Using a refractometer to measure sugar content is a fairly straightforward process. Here are the steps to follow: 1. **Calibrate the refractometer**: Begin by calibrating your refractometer using distilled water or a calibration solution provided by the manufacturer. . **Temperature adjustment (if required)**: Some refractometers offer .A refractometer must be sensitive to the required accuracy, with features that eliminate potential confounding issues,” says Chapman. A 0 handheld refractometer should not be used for pharmaceutical QC, but such an instrument might work for educational settings or rapid raw materials testing.

To select the right refractometer, it is helpful to define the required measurement range. There is real potential for savings when purchasing a new refractometer, as refractometers with a small measurement range are usually more cost-effective compared to measuring devices that cover the entire measurement range.If available, use the instrument’s on-board audit trail that logs who has done what so that any unauthorised changes to the instrument can be easily traced. 6. Sample preparation is the key to good measurement For handheld refractometers, this could simply be degassing soda from canned drinks using cups or theQC: Quality Control 6.0 REFERENCE: NIL . N.B after use put all the LDPE bag .outer and threads to the designated place. Methods No 02. APPARATUS: a). Abbe’s Refractometer. b). Source of light. c). A dropper or jet tube.

Most refractometers instead make use of the critical angle effect. When light passes from a more dense to a less dense medium, it may be refracted, as shown in Figure 28.18(b) . When readings are required in large numbers or continuous monitoring of a process is called for, an automatic type of Abbé refractometer may be used. .There are four main types of refractometers, traditional handheld refractometers, digital handheld refractometers, laboratory or Abbe refractometer and incline process refractometers. The Abbe refractometer . Brix refractometers are often optimized for a specific concentration range, according to their specific use. 8 For example, a Brix refractometer designed for honey quality control is optimized for higher . How to Use a Refractometer. Using a refractometer involves proper preparation and calibration. Below is a step-by-step guide: Calibrate the Refractometer: Before using, ensure your refractometer is calibrated. Place a few drops of distilled water on the refractometer prism, close the cover plate to spread the water evenly, and adjust to read zero (or the specific .

A digital refractometer measures the refractive index or related values of a liquid sample using the total reflection method. This measurement is done automatically, which reduces operator influence and enhances accuracy. Using a small sample volume (0.5 to 1 mL), highly accurate measurements of the index of refraction are performed in seconds.

In order to effectively use a refractometer, it is important to follow a few key steps: calibrating the refractometer, preparing the sample, and reading and interpreting the results. Calibrating the refractometer. Before using a refractometer, it is crucial to calibrate the instrument to ensure accurate and precise measurements. Depending on the quality of the refractometer, variation in calf body weight, age at first feeding and many other factors, the difference (0.3 g/dl) may not be discernible using a hand-held refractometer. A more accurate clinical refractometer or other tests to directly measure IgG should be used in this case. Summary. Well, there you have it.18 Top Tips For Quality Refractometer Results part 1: Refractometers 101 & The need for Quality Control by Peter Abbey April 02, 2020 This blog was originally posted on our sister site www.bellinghamandstanley.com and over the coming few weeks we will be syndicating the content for our readers at Refractometer Shop.Refractometer Uses in Industry and Selection By Angelo DePalma, PHD. Refractometer uses: Characterizes fluids based on their refractive index –the refraction occurs due to the change in the speed of light as it travels through a material of one density to one of different density. By definition a vacuum has a refractive index of 1, and the refractive index of a solution or pure .

How to Place the Sample on the Refractometer. When using a refractometer, it is important to place the sample correctly so that an accurate reading can be obtained. To do this, first make sure that the prism plate of the refractometer is clean and free from any foreign material. Next, place a few drops of the sample onto the center of the prism .The J57HA Automatic Refractometer is designed specifically for food quality testing and QC: Absolute accuracy regardless of sample type Keywords J57HA Automatic Refractometer, Refractometers, Food Quality Testing, QC, Heavy Use Refractometers, Electronic Temperature Control, Refractive Index, Brix, Calibration, Laboratory, No Water Bath .

If you are using a model with ATC, you can simply use the reading you have. If you do not have ATC, then you must use a chart included with the refractometer to get the compensated reading. You simply use the ambient temperature and the reading to get a value that must be added or subtracted from the reading to make the compensation. The refractometer readout shown above is measuring 30 degrees Brix. Other Types of Refractometers. Digital refractometers require a drop of the tested solution to be placed in a well. That well is illuminated by a light source, usually an LED light, and the meter interprets the light transmission into refractive index or whatever unit of measure the .

refractometer quality control

polarimeter calibration solution

webThe latest tweets from @greatm8sfm

6 what qc is required when using a refractometer|refractometer maintenance guide